Rayon Energy Pvt. Ltd. Transformer Oil Filtration Machine

Rayon Energy Pvt. Ltd. Established in 2013. We are Manufacturers, Exporter, Supplier of Transformer Oil Filtration Machine, Transformer Evacuation System, Oil Storage Tanks and Other Industrial Oil (Hydraulic/Lube/Turbine/Quenching Oil Filtration Machine).

Rayon India has earned a reputation for manufacturing and supplying the best in class Transformer Oil Filtration Machines. These machines are designed to filter and purify transformer oil, which is crucial for the smooth operation and longevity of transformers. The Transformer Oil Filtration Machines offered by Rayon India are equipped with advanced features newly technology that make them efficient, reliable, and easy to operate. They effectively remove impurities, moisture, and other contaminants from transformer oil, leading to improved insulation and dielectric strength. We have already supplied our machines in Nepal, Bhutan, and African Countries which have been working satisfactorily since long. We also have supplied our machines to very reputed and renowned companies like KEI, JINDAL, MEGHA ENGINEERING & INFRASTRUCTURES LTD. (MEIL), PATANJALI, RVNL, RUNGTA MINES, MSP METALLICS LTD, NEA (Nepal Electricity Authority), BPCL (Bhutan Power Corporation Limited), SCCL (S). are few names of them.

Rayon India's commitment to quality and customer satisfaction has made it a trusted name in the industry. With its high-quality Transformer Oil Filtration Machines, Rayon India helps businesses to ensure the smooth operation of their transformers and reduce maintenance costs. Transformers are vital components of power generation systems, and their efficient performance is essential for the smooth functioning of power grids. The performance of transformers is directly related to the quality and purity of the insulating oil used in them. Therefore, it is crucial to have high-quality and pure insulating oil to ensure the transformer performs at its peak level. Transformer Oil Filtration Plants operate on the principle of filtering out impurities and contaminants through stage-wise filtration. The plant removes water, dissolved gases, acetylene, hydrogen, and other gases through vacuum extraction, ensuring that the insulating oil is free of impurities. Additionally, the plant employs the ion exchange principle to remove acids from the transformer oil, further improving its quality.

Moreover, the Transformer Oil Filtration Plant is equipped with an evacuation system that dries out the system during maintenance, preventing the formation of moisture and other contaminants. This feature helps to maintain the purity and quality of the insulating oil and ultimately improves the performance and longevity of transformers.

Transformer Oil Filtration Plant

Rayon India offer a comprehensive range of Transformer Oil Filtration Plants that are designed to ensure the purity and quality of the insulating oil used in transformers. The performance of transformers is significantly affected by the presence of moisture, dissolved gases, and unwanted particles in the insulating oil. Contaminated transformer oil loses its essential characteristics, such as dielectric strength, resistivity, and loss factor. Excessive moisture in transformer oil leads to the formation of acids and sludge, which can cause severe damage to transformers and reduce their operational lifespan.

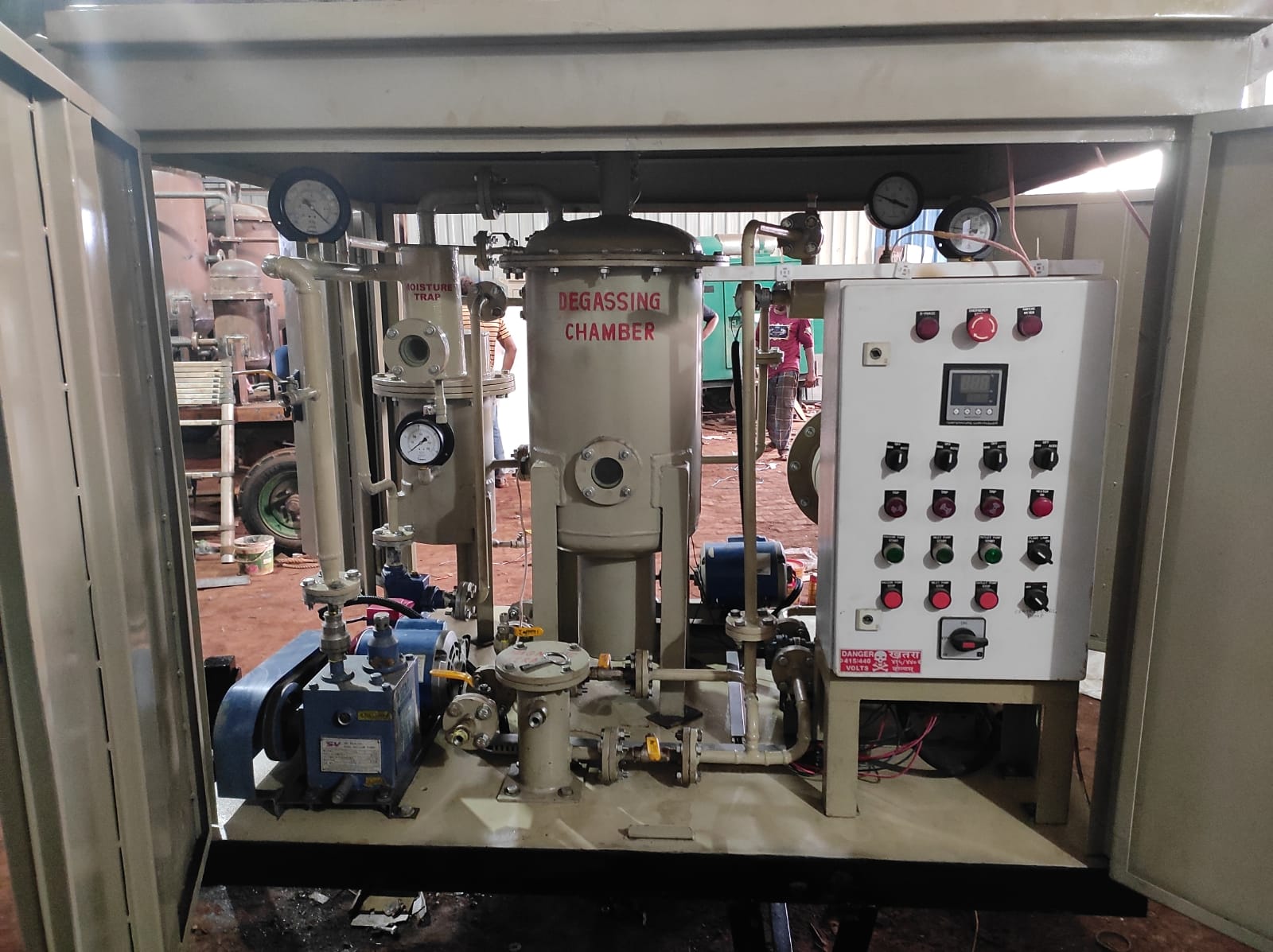

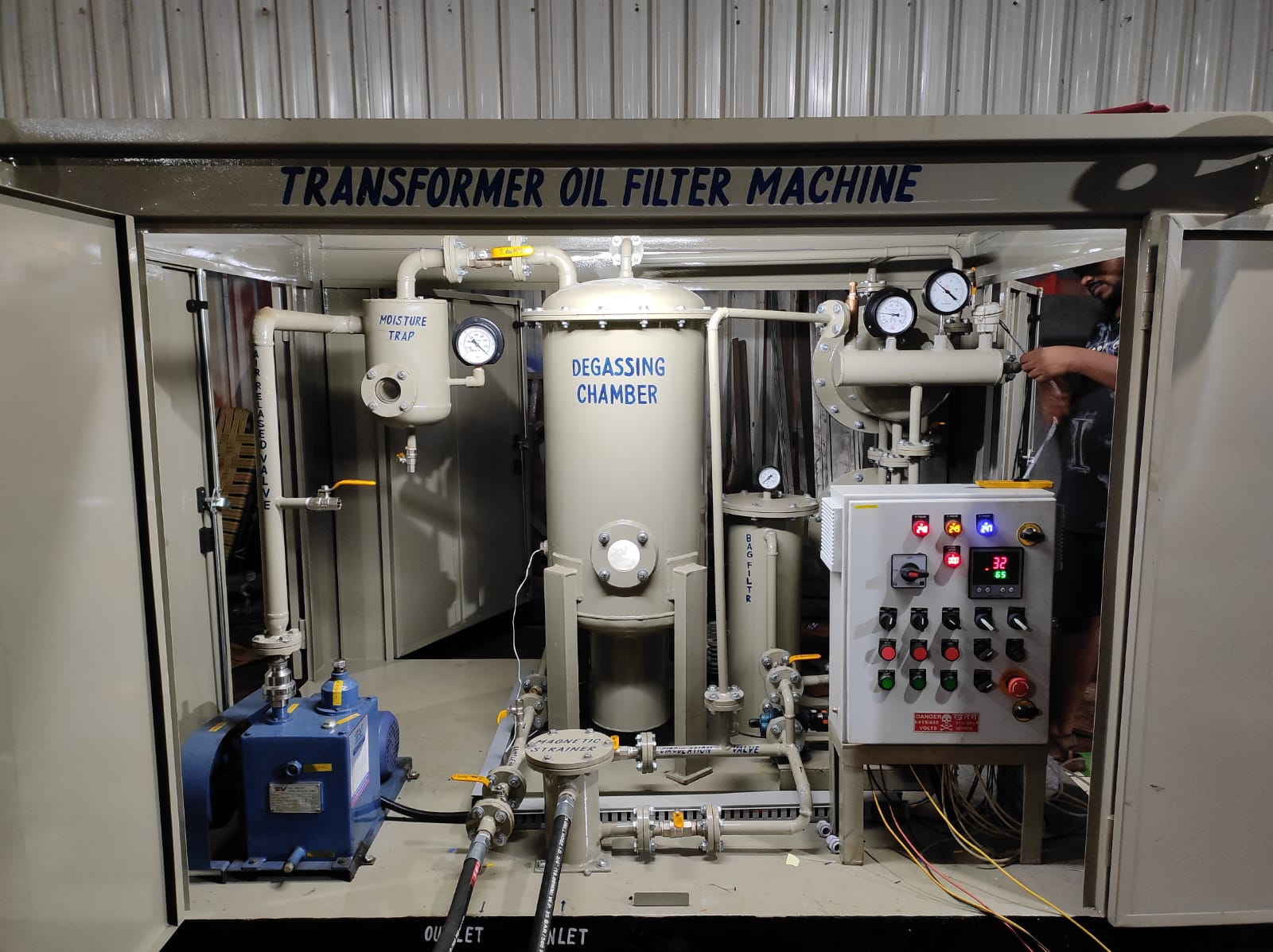

Our Transformer Oil Filtration Plants employ the latest technology features to remove impurities and contaminants from the transformer oil, ensuring that it is free of moisture, dissolved gases, and unwanted particles. The filtration process employs a stage-wise filtration system, vacuum extraction, and the ion exchange principle to filter out impurities and ensure high-quality insulating oil. , our Transformer Oil Filtration Plants come equipped with an evacuation system that removes moisture from the transformer oil during maintenance, preventing the formation of acids and sludge. This feature significantly reduces maintenance costs and prolongs the lifespan of transformers.

Our Transformer Oil Filtration Plants are a reliable solution for maintaining the purity and quality of transformer oil, ensuring the efficient performance and longevity of transformers. With our advanced technology and cutting-edge features, we provide a comprehensive range of Transformer Oil Filtration Plants suitable for various applications and industries.

Ultra High Vacuum Transformer Oil Filtration

Rayon Energy is a well-known name in the manufacturing and supply of Ultra High Vacuum Transformer Oil Filter Plants. These plants are designed to filter transformer oil and improve the operational lifespan of transformers. They are particularly essential for the electrical industry and power plants where the removal of dissolved gases and oxidation products is crucial. The Ultra High Vacuum Transformer Oil Filter Plant is a compact and user-friendly equipment that comes with a degassing column available in Two and Three-stage versions. Its simplicity in operation makes it easy for operators to use without encountering any difficulties.

Rayon Energy has established a reputation for excellence in the industry with its reliable and efficient Ultra High Vacuum Transformer Oil Filter Plants. The equipment is essential for the smooth operation of transformers and power plants, and its compact size and ease of use make it a convenient option for various users. Ultra High Vacuum Transformer Oil Filtration is an essential process that helps to increase the lifespan and efficiency of transformers. This process involves removing dissolved gases, moisture, and other contaminants from the transformer oil, which can cause severe damage to the transformer and affect its performance.

The process of Ultra High Vacuum Transformer Oil Filtration uses a degassing column that operates under high vacuum and effectively removes dissolved gases and other contaminants from the transformer oil. This process improves the insulation and dielectric strength of the transformer, which leads to a reduction in maintenance costs and enhances the lifespan of the transformer. Ultimately, Ultra High Vacuum Transformer Oil Filtration helps to ensure a stable and reliable power supply, which is crucial for various industries and applications.

Types of Machines

Characterstics of Oil After filtration

| Parameter | Before Filteration | After Fliteration |

|---|---|---|

| Break Down Voltage KV | 20-30 kv | 60 to 70 kv |

| Moisture Removal | 50-100 ppm | 5 to 3ppm |

| Gas Content | < 10% by volume | 1% by volume |

| Fillter Particles | Visible to naked eye | 1 to 0.5 micron |

Options Available with Machines

Our Products

Our Gallery